Automation Development Inc

Automation Development Inc

~ Assembly Machinery ~

~ Custom Turnkey Automated Machinery ~

Call Toll Free 1-800-349-0528

Automation Development Inc

Automation Development Inc

~ Assembly Machinery ~

~ Custom Turnkey Automated Machinery ~

Call Toll Free 1-800-349-0528

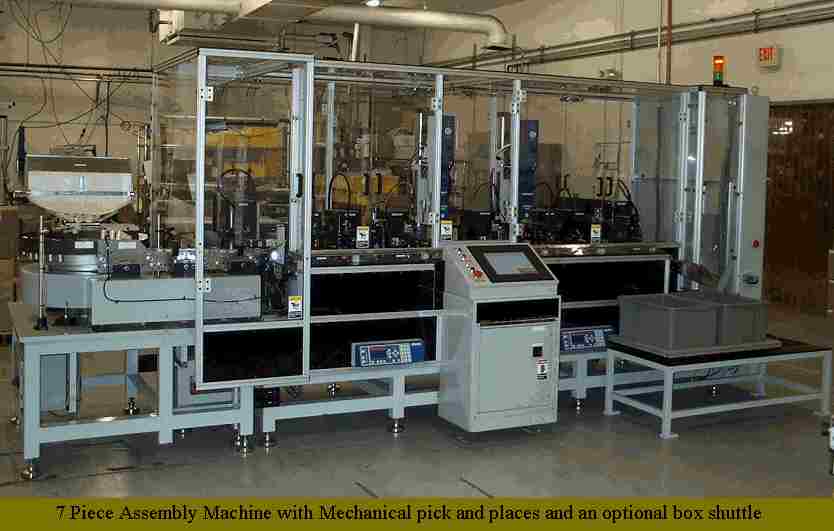

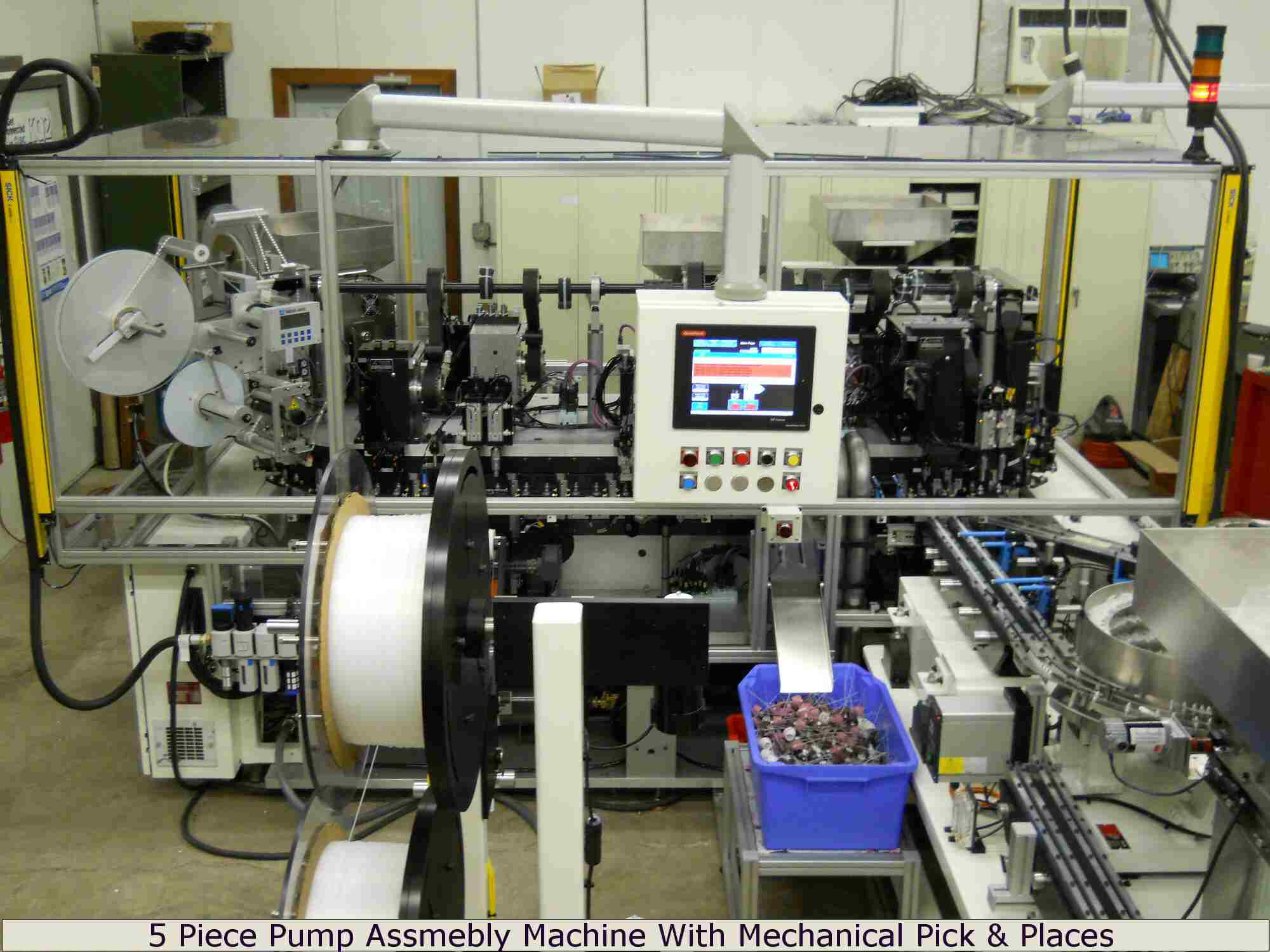

Chassis Style Indexing Machines

Inline assembly machines are used for higher part count assemblies or where space is at a premium. Fully automatic inline machines allow better access to machine due the linear configuration. They are also a good option for assembly inline with molding operations as they use a rectangular footprint which allows placement closer to the molding equipment.

Inline assembly machinery is very useful for assemblies of four or more components. They provide more design flexibility and much better operator access than what is practical on a rotary dial system. Systems are available in an "over-under" chassis or "carousel" chassis. Typical speeds for these systems range from 10-30 cycles per minute with pneumatic pick and places to 50 cycles per minute or higher with mechanical, cam driven pick and places.Higher throughputs are achieved by tooling multiple parts and making multiple assemblies per cycle.

While inline style machines tend to towards a higher base price they do provide advantages over rotary style assembly machines in some cases.

Fully Tooled Chassis Style Indexing Machines

Press the play button to watch the machine in action

| Launch in external player |

| Launch in external player |

Automation Development Home Page

Dial type rotary indexing machines

Inline chassis indexing machines

High speed continuous motion machines

Assembly machines inline with molding machines. End of arm tooling for molding robots

Packaging and Robotic Loading machines

Design and engineering capabilities

Machining / fabrication capabilities

Machine vision and electrical controls capabilities

About Automation Development - Contact Us - Directions

Automation Development Inc.

73 Container Drive

Terryville, Ct 06786

Call Toll Free 1-800-349-0528

Phone 1-860-583-0852 - Fax 1-860-583-6471